1) You’ll bring the material to a polished finish.

- Higher polish equals brighter more vibrant colors in the end.

2) Submerge the in “Multi-Etch” for just 5 seconds.

- You can skip this step but “Multi-Etch” really helps bring out the colors so we HIGHLY recommend it.

*Pro-Tip 1 – If you want more depth to the layers, like you get when you acid-etch damascus, then you can leave the material in the “Multi-Etch” until you get the depth you want. Brushing the material with a soft brush every minute will help you achieve the most even etch. If you plan on doing a deeper etch then you’ll want to polish the ring after multi-etching cause after 10 seconds or so in the “Multi-Etch will turn the surface to a matte finish and you want polish finish before flaming.

*Pro-Tip 2 – Titanium will start to build a hard anodized layer on the surface if it sits out in the open for too long so it’s smart to flame the ring within a hour or two of Multi-Etching. You can however leave the ring in distilled water for up to a day, this will prevent the titanium from anodizing.

3) Clean the ring alcohol or acetone and make sure its completely dry before moving forward.

- Be sure to blow away any small particles that might be left from drying with your towel.

4) Once there you’ll want to hang the material from a wire to flame it.

- Hanging it from the wire will help get an even color, laying it on a metal table or something similar will suck the heat out of section touching the metal, causing uneven coloring.

5) To flame we like to use a smaller torch for smaller parts (like a cooking torch) so we can control the heat better, goal is to evenly heat up the part.

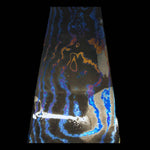

- As you heat the material you’ll see the titanium start to turn gold and brown, with more heat the titanium you’ll see the ring turn from brown to purple, if you continue heating it the purple will turn to blue.

6) Once you achieve the color you’re wanting, stop heating and immediately submerge the material in distilled water.

- Submerging the material immediately is what seals in the color of the titanium and zirconium. The colors won’t fade when touched if you do this.

*Pro Tip 3 – If you don’t like how the color turned out then you can soak in the Multi Etch, The anno layer will turn to a grey film so brushing it every 30 seconds is important, keep going till the grey film is removed and your left with a silver matte finish. Restart at step 2 to re color.

Multi-Etch website has a lot of good information/videos on their website, worth reviewing prior to using. https://www.multietch.com

Click here to download instructions "How to Color Damtanium and Zirmascus"