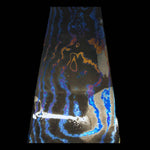

Damtanium Twist Rod

Damtanium, a form of Titanium Damascus, is a truly exclusive and unique material. This intricate material is meticulously crafted by first heating the titanium layers to 1900 degrees. Once to temperature we fuse the layers together with our Nazel pneumatic hammer. Finally the fused material is rolled out on our rolling mill and pattern pressed with a 250 ton hydraulic press. The colors of Damtanium are achieved by either Flame anodizing with a torch or Electric anodizing with electric anodizer.

To guarantee the most luminous finish and vivid colors, only the highest quality of Titanium—Grade 5 and Grade 2—is used in the creation of this material. This choice of premium titanium not only enhances the aesthetic appeal but also ensures the highest standard of quality and durability. The result is a material that doesn't just captivate the eye but also stands the test of time, perfect for creating objects of both beauty and function.

Damtanium is Titanium Damascus—leveled up.

We start by heating premium Grade 5 and Grade 2 titanium to 1900°F. Then we fuse the layers using our Nazel pneumatic hammer, press them flat on our rolling mill, and pattern them with a 250-ton hydraulic press.

The result? A high-contrast, twisted pattern that’s equal parts performance and flex.

Colors come alive through flame anodizing or electric anodizing—turning each round bar into a piece of art that’s ready to be machined, turned, or shaped into something unforgettable.

Damtanium Twist Rods are made to grab attention—and hold up for life.

How to Color Damtanium and Zirmascus