Today, Damascus steel is one of the most popular materials for making knife blades. Often advertised as being much stronger than “regular” steel knives, or able to hold a sharper edge, many consumers end up wondering as to what is the difference between Damascus steel and other knife blade materials.

Often described as the same steel used for making Japanese Samurai swords, in fact, Damascus steel has been in use as a material for swords since about 1100 AD. This material was known for being able to cut through very hard materials. It was often claimed that a sword made of this steel would cut through low-quality swords and even solid rock.

First developed in India and Sri Lanka, the process began with high-carbon steel known as wootz steel. Recognized for its unusually high purity, wootz steel first developed as early as 300 BC and became the steel used for Damascus steel around 1100 AD. The original method for making Damascus steel was lost to the ages, though it is believed to have involved a series of cooling and heating processes to strengthen the steel. Damascus steel gains its strength from microscopic nanotubes of carbon in the steel. These combine to form a stiff, strong material.

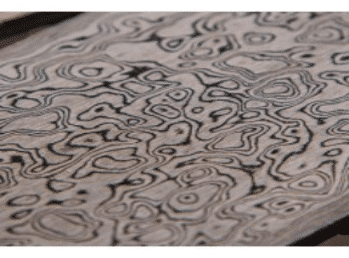

The first modern Damascus blades were made in the 1940s, with growing popularity in the 1970s. Today, the term “Damascus” has come to mean any steel with a visible grain pattern. Modern methods for making stainless Damascus result in a laminated effect, with many layers of folded steel comprising the blade. This process, known as pattern welding, requires two types of steels, one with a high content of nickel. By folding and twisting, the steel gains its characteristic layered or laminated appearance.

Today, Damascus steel tends to be more labor-intensive than other processes, such as Bessemer steel, making it more expensive. Still, Damascus steel is a remarkable metal. Many craftsmen who want to recreate the old ways of knife making uses this material. Compared to stainless steel, a standard knife blade material, Damascus steel holds its edge longer and is harder to break. However, it is possible for the blade to tarnish or rust, so your Damascus steel blade must be properly maintained. Also, many Damascus steel blades are considered a work of art due to their layered appearance.

Although the microscopic appearance of modern Damascus steel resembles that of old steel, it is not believed that ancient sword makers used the same process to achieve the exceptional qualities of stainless Damascus. Should you opt for Damascus steel for your next knife purchase? Maybe, but it depends on the use of the knife.

If you are looking for a beautiful collector’s knife, this type of steel is an excellent choice. It is also ideal for those who are good about cleaning their knife between each use, yet don’t want to be constantly sharpening a worn-down edge. Damascus steel offers a unique blend of aesthetic and practical qualities, good reason for its continuing popularity as a knife material.

Lucas Lippi says

I want to win an argument against my brother, who claims that stainless still is better than Damascus. Can you give a list of references or work cited that backs up what you wrote? Thanks!

J Mendenhall says

Is the term Damascus Twisted Steel a correct term?

Jesse Harber says

Twisted damascus steel would be. Its just damascus steel that was twisted to change the pattern